Specifications + Dimensions

| M1266H12 Specifications: | |

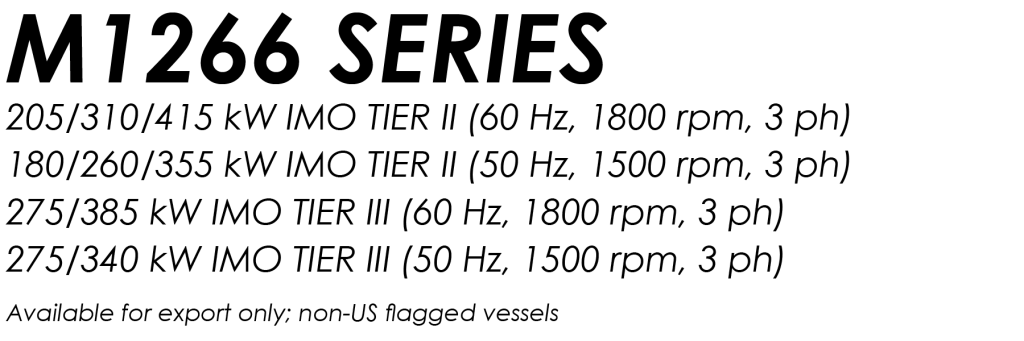

| 60 Hz @ 1800 rpm | 205 kW |

| 50 Hz @ 1500 rpm | 180 kW |

| Cylinders: | I-6 |

| Bore: | 4.9 in (126 mm) |

| Stroke: | 6.5 in (166 mm) |

| Displacement: | 758 cid (12.42 ltr) |

| Aspiration: | Turbo and Aftercooled |

| Length: | Consult Factory |

| Length with Enclosure: | Consult Factory |

| Width: | Consult Factory |

| Width with Enclosure: | Consult Factory |

| Height: | Consult Factory |

| Height with Enclosure: | Consult Factory |

| Weight: | Consult Factory |

| Weight with Enclosure: | Consult Factory |

| M1266H13 Specifications: | |

| 60 Hz @ 1800 rpm | 275 kW |

| 50 Hz @ 1500 rpm | 275 kW |

| Cylinders: | I-6 |

| Bore: | 4.9 in (126 mm) |

| Stroke: | 6.5 in (166 mm) |

| Displacement: | 758 cid (12.42 ltr) |

| Aspiration: | Turbo and Aftercooled |

| Length: | Consult Factory |

| Length with Enclosure: | Consult Factory |

| Width: | Consult Factory |

| Width with Enclosure: | Consult Factory |

| Height: | Consult Factory |

| Height with Enclosure: | Consult Factory |

| Weight: | Consult Factory |

| Weight with Enclosure: | Consult Factory |

| M1266H22 Specifications: | |

| 60 Hz @ 1800 rpm | 310 kW |

| 50 Hz @ 1500 rpm | 260 kW |

| Cylinders: | I-6 |

| Bore: | 4.9 in (126 mm) |

| Stroke: | 6.5 in (166 mm) |

| Displacement: | 758 cid (12.42 ltr) |

| Aspiration: | Turbo and Aftercooled |

| Length: | Consult Factory |

| Length with Enclosure: | Consult Factory |

| Width: | Consult Factory |

| Width with Enclosure: | Consult Factory |

| Height: | Consult Factory |

| Height with Enclosure: | Consult Factory |

| Weight: | Consult Factory |

| Weight with Enclosure: | Consult Factory |

| M1266H23 Specifications: | |

| 60 Hz @ 1800 rpm | 385 kW |

| 50 Hz @ 1500 rpm | 340 kW |

| Cylinders: | I-6 |

| Bore: | 4.9 in (126 mm) |

| Stroke: | 6.5 in (166 mm) |

| Displacement: | 758 cid (12.42 ltr) |

| Aspiration: | Turbo and Aftercooled |

| Length: | Consult Factory |

| Length with Enclosure: | Consult Factory |

| Width: | Consult Factory |

| Width with Enclosure: | Consult Factory |

| Height: | Consult Factory |

| Height with Enclosure: | Consult Factory |

| Weight: | Consult Factory |

| Weight with Enclosure: | Consult Factory |

| M1266H32 Specifications: | |

| 60 Hz @ 1800 rpm | 415 kW |

| 50 Hz @ 1500 rpm | 355 kW |

| Cylinders: | I-6 |

| Bore: | 4.9 in (126 mm) |

| Stroke: | 6.5 in (166 mm) |

| Displacement: | 758 cid (12.42 ltr) |

| Aspiration: | Turbo and Aftercooled |

| Length: | Consult Factory |

| Length with Enclosure: | Consult Factory |

| Width: | Consult Factory |

| Width with Enclosure: | Consult Factory |

| Height: | Consult Factory |

| Height with Enclosure: | Consult Factory |

| Weight: | Consult Factory |

| Weight with Enclosure: | Consult Factory |

Notes

- Prime kW ratings for 3Ø at 0.8 power factor. Consult factory for deration factors.

- Net flywheel hp rating for fully equipped engine at rated speed under SAE J816b.

- Based on prime kW rating at 1800 and 1500 RPM. Fuel rate may vary depending on operating conditions.

- Data for units with hydrolastic mounts, heat exchanger cooling and 3 phase generator ends. Dimensions and weight are affected by optional equipment, AC output, phase, exhaust and cooling configuration.

- Consult factory for data on enclosures for sets with InSep.

Dimensions and weights are subject to change without notice, they are not intended for installations.

Contact a factory representative for the current installation data

Features + Benefits

• Six cylinder, four cycle, in-line, liquid cooled, overhead valve, marine diesels based on heavy-duty industrial engine blocks

• Balanced alloy steel and induction hardened crankshaft

• Replaceable valve seats and guides

• Strong three ring steel pistons for long-life reliability

• Gear-driven seawater pump and freshwater pump

• Drive belt powers the alternator

• Replaceable, strength-optimized wet cylinder liners for long life and low rebuild costs

• Electronically controlled high-pressure fuel injection system provides individual control in each cylinder for low exhaust emissions and superior fuel economy.

• High torque at low revolutions. (1800 or 1500 rpm)

• Full flow spin-on duplex elements

• Gear driven fuel transfer pump with primer

• Flexible fuel lines routed to fuel manifold on base frame for easy installation of vessel’s hard piping

• 600 hour oil change interval when fuel and oil requirements are met

• Force feed lubricating by gear oil pump

• Full flow, spin-on oil filter

• Centrifugal oil cleaner to extend oil change intervals

• Freshwater, plate-type, full flow oil cooler reduces heat and thermal breakdown of lube oil

• Large capacity oil pan

• Floating, cast aluminum, rocker cover

• Lube oil drain for easy changes

• Dry air filter silences intake noise

• Aftercooler with marine quality, cupro-nickel, single pass element

• Turbocharged for increased output

• Freshwater cooling system with three thermostats for quicker warm-ups

• Heat exchanger cooling includes: Gear driven, flexible impeller seawater pump.

• Cast aluminum expansion tank with brass filler neck. Cast-iron exhaust manifold has single pass freshwater flow for even temperature control, fast warm-up and no hot spots

• Titanium plate heat exchanger – no zinc anode protection necessary

• Two thermostats for quick warm-ups and safety

• Cast-iron exhaust manifold for reliable temperature control

• Engine supplies SAE J1939 data stream through a CAN bus plug for optional engine

monitor

• Negative ground, 24 volt DC system with circuit breaker, starter motor and battery

charging alternator with regulator. Isolated ground optional

• Standard digital controller displays engine hours, coolant temperature, oil pressure,

DC voltage, and includes start-stop controls. Increased ease of paralleling through

controller

• Engine and panel are pre-wired with terminal strips

• Low oil pressure and high coolant temperature safety shutdown system included

in controller

• Generators meet or exceed class society standards. All have class H insulation,

accessible diodes, oversized ball bearings, marine grade shafts and conservative

90°/50° heat rise ratings

• Engines and generators are torsionally matched for long life

• Automatic voltage regulator gives fast response to electrical load changes. Voltage

is regulated to ±0.5% (one half of one percent) over the entire range from no load

to full load

• Isochronous electronic governor for 0% AC frequency droop

• PMG (permanent magnet generator) to power AVR for 300% short circuit capability

for “classed” vessels

• Standard hydrolastic mounts isolate 98% of hull vibration

• Belt guard protects operator even on sets in sound enclosures

• Sparkling white IMRON® polyurethane paint for protection and visibility

• Operator’s and parts manuals

• IMO Tier 2 and Tier 3 compliant

• Available certification from CCS upon request.